Business Line 1

One-Stop ShopAutomotive Hub

On going In New Cairo

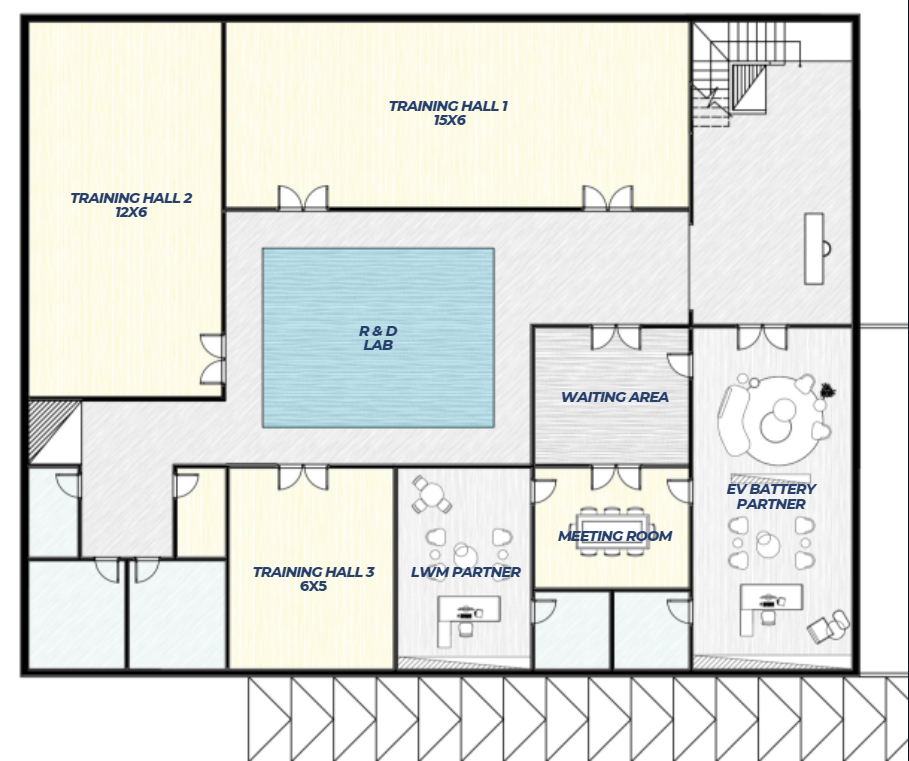

- Automotive Hub Total Built Up Area: 3000 sqm

- Work Capacity: 40 cars per day

- Training Capacity: 3 training halls

- Provisioned to expand the operational area up to 6600 sqm

A one-stop shop facility

combining automotive (EV & ICE) services, training, and R&D all under one roof consists of the following SBUs:

- Electrical /mechanical workshop

- Dedicated dry area for EV Repair

- Bodyshop

- Smart Repair

- Training center, R&D Lab

- Pre-owned car center

- Extended Warranty & Service Package

- Leasing & Fleet mgmt.

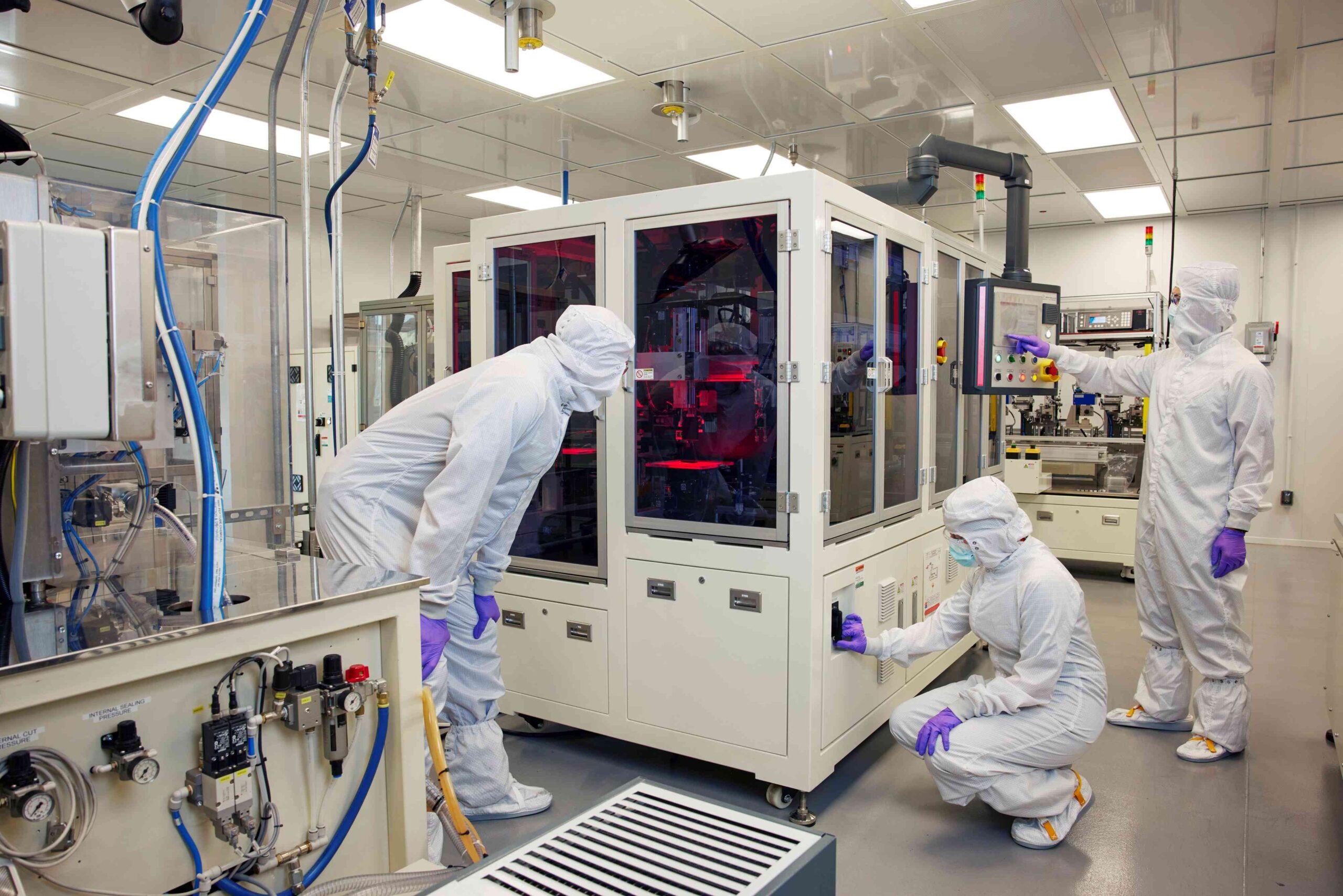

R&D Lab

An ongoing effort to develop and enhance products and services, undertaken by tech engineers and technology partner. The R&D lab will focus on:

- Automotive smart repair technology.

- Automotive components made of lightweight materials.

- Energy Storage Systems (EV Batteries)

Training & Education

Business Line 2

Manufacturing Automotive Components(Planning phase)

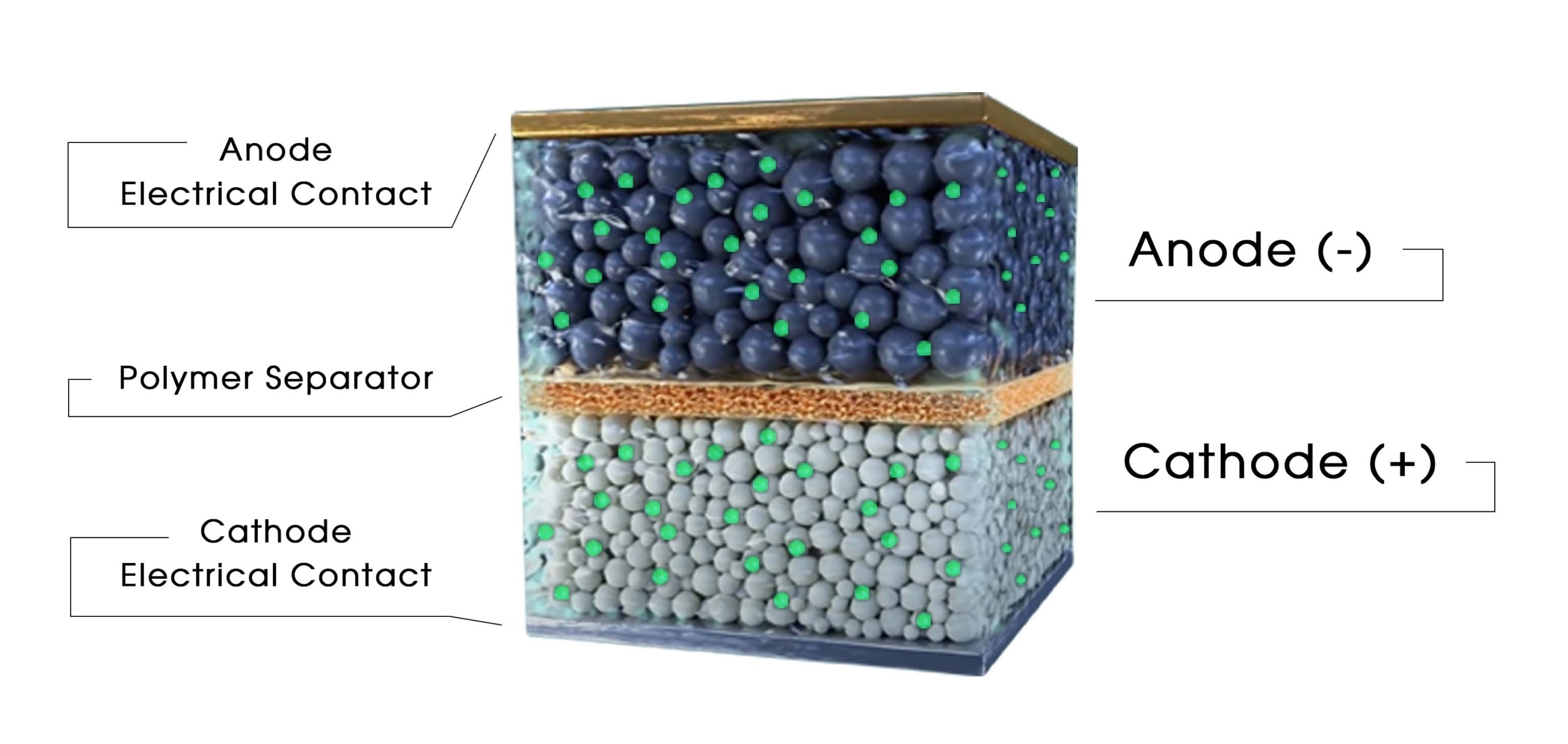

Component 1

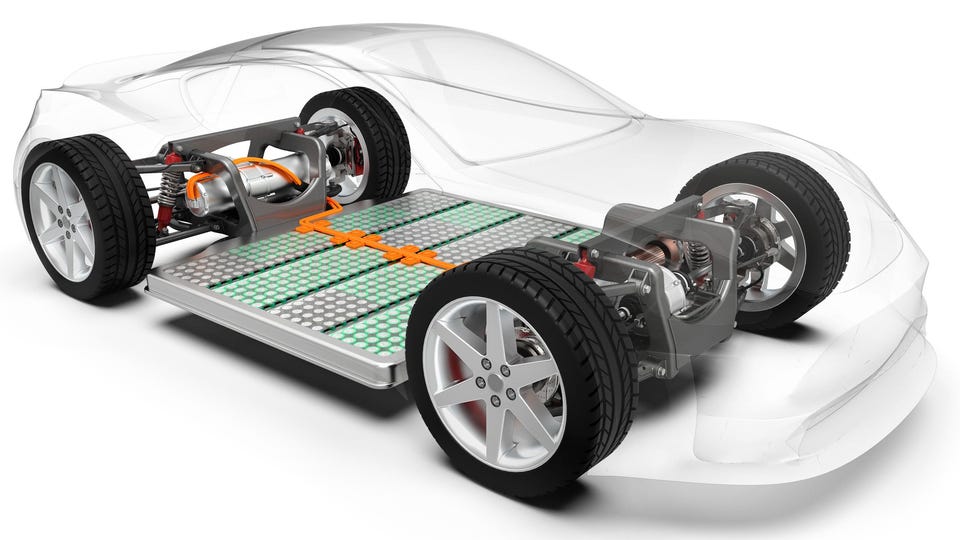

EV Battery Enclosure made of Lightweight Materials

Why Composites & Lightweight Materials (Aluminum&CFRP)?

- High strength / weight ratio

- Improved Strength/Stiffness per unit area

- Do NOT rust and require very minimal maintainance

- Excellent fatigue resistance

- Thermal Insulator (CFRP)

- Electric Insulator (CFRP)

- Freedom of design (CFRP)

- Recyclable

- CFRP 1/5th of steel weight

- Aluminum 1/3rd of steel weight

Component 2

Cost Effective Sodium Ion Battery Cell

The global market for sodium ion batteries is experiencing exponential growth, driven by increasing demand and technological advancements. According to projections by the International Energy Agency, production capacity is expected to grow significantly, with Chinese manufacturers leading the charge. By 2030, it is estimated that nearly 95% of sodium ion batteries will originate from China.

In economic terms, the market value of sodium ion battery technology is forecasted to surpass 1 billion euros by 2030, with compound annual growth rates exceeding 10% until the end of the decade. These figures underscore the immense market potential and lucrative opportunities awaiting stakeholders in the sodium ion battery industry.

As the demand for sodium ion batteries continues to soar, establishing a manufacturing facility presents a strategic opportunity to capitalize on this burgeoning market. By investing in state-of-the-art production capabilities, you can position your company at the forefront of sodium ion battery manufacturing, catering to diverse industries and applications.

At DYNATECH, we specialize in providing comprehensive project development for sodium ion battery manufacturing, from research and development to production scale-up. With our expertise and innovative technologies, we can help navigate the complexities of establishing a manufacturing facility, ensuring efficiency, quality, and competitiveness in the rapidly evolving sodium ion battery market.

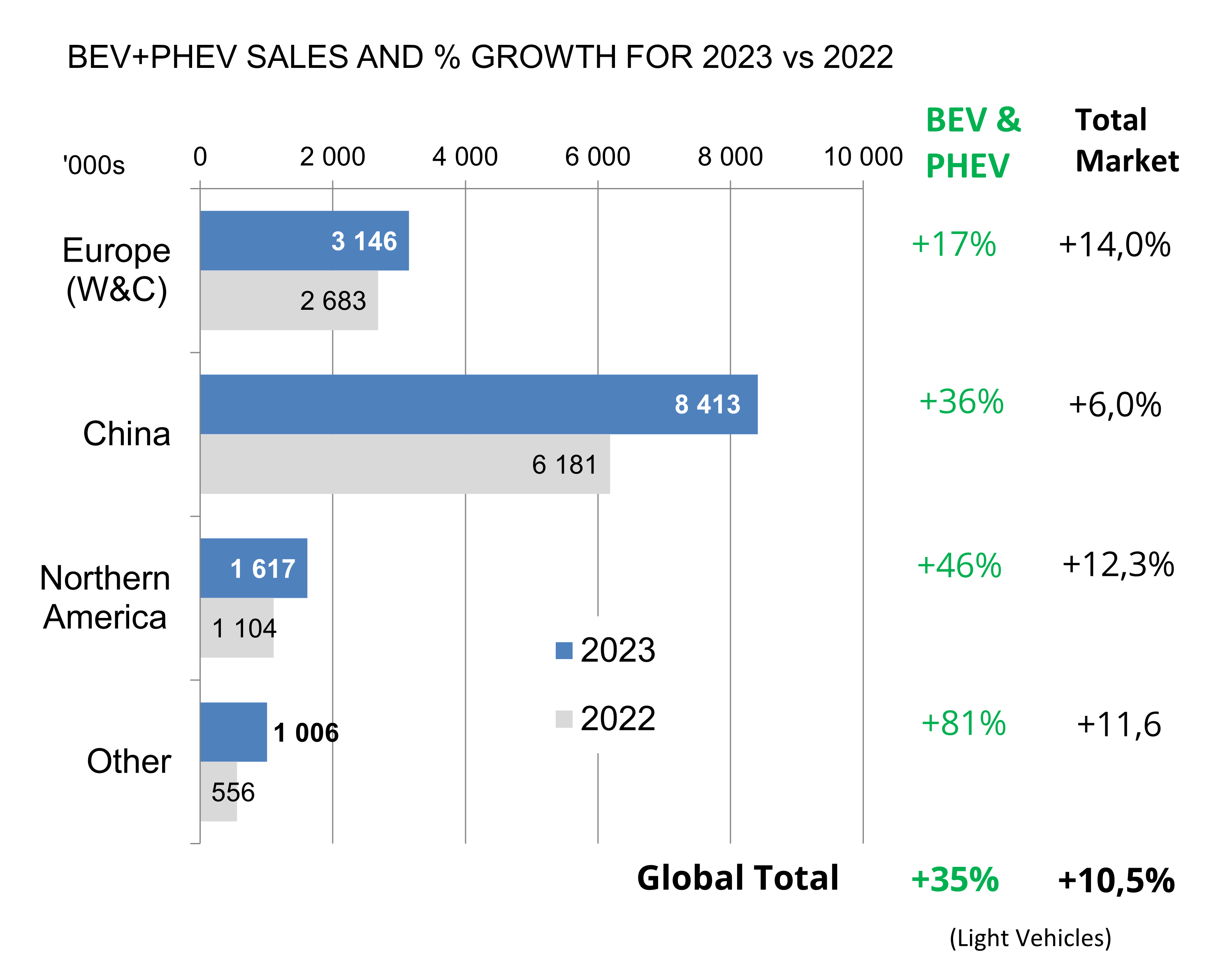

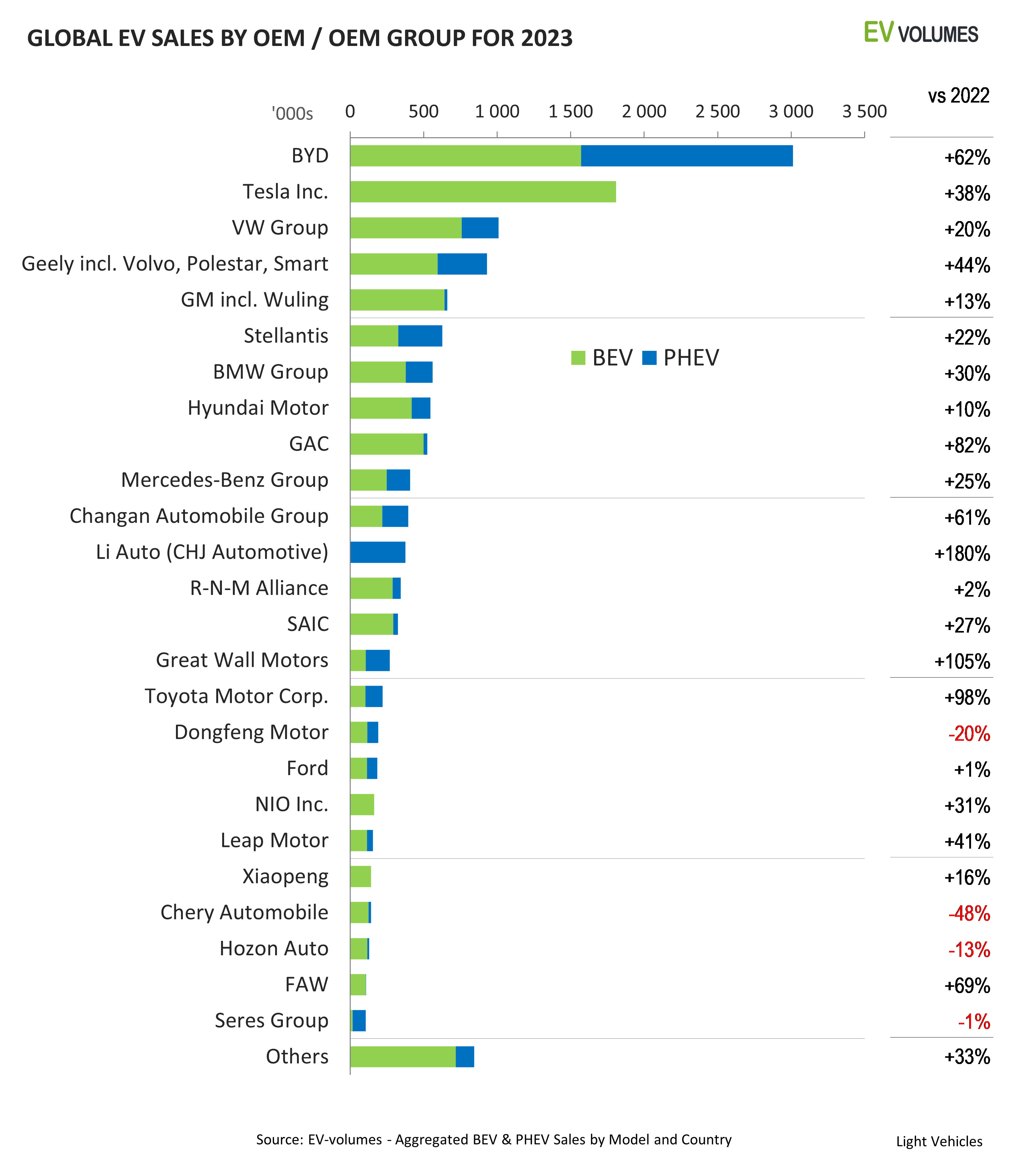

EV Market Insights

Global EV Sales

- Globally, EVs outperformed the market by a good margin, increasing volume by 35% in 2023.

- China is, by far, the largest EV market, with 8.4 million units in 2023 and 59% of global EV sales.

- The number of EVs in operation worldwide reached 40 million at the end of 2023.

- For 2024, sales of 17,8 million EVs are expected, a growth of +25% over 2023, with BEVs reaching 12,8 million units and PHEVs reaching 5 million units, compared to 10.5 million sales in 2022.

- To reach the Net Zero target by 2050, global EV sales must reach 350 million EV cars by 2030.